Previous

Next

Seamark - HOng Kong

Seamark ZM – Hong Kong, is in design and development of BGA Rework System, X Ray Inspection Equipment and SMD Reel Component Counting Machines.

X-Ray Inspection Machine for PCBA, Semiconductor, Packing components for Semiconductor, Packing components

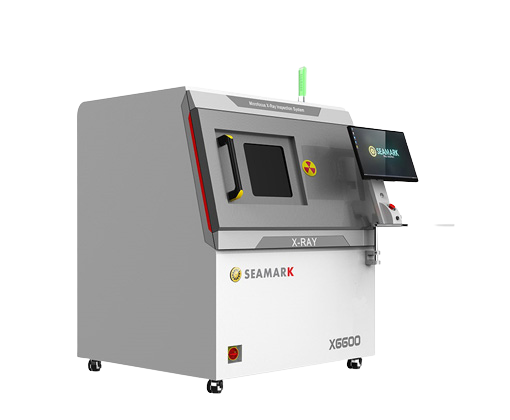

X6600

- 90KV 15 um closed X-ray tube, with long life, maintenance in free

- 1.3million high resolution digital flat panel detector

- Color image navigation

- Automatic programming detection and automatic analysis Not good or Pass

- More modular panels observation point setting

- By the space bar to adjust stage speed: Slow, Constant and Fast

- Keyboard control X, Y, Z axis motion and the inclined angle

- User can detect the samples automatically by programs

- Large navigation window, the image is very clear, mouse clicks will move the stage to a position that you need

X-Ray inspection equipment for SMD Reel

X1000

- Automatic component recognition – Automated parameter setting and counting of unknown components

- Intelligent database on site

- Verification of results through plausibility check

- Counting of component chains

- Quad-Count-Fourfold counting:we count four bundles in 15 seconds with a scan

- Stick & Tray:high precision counting in<15 seconds

- Order counting (exact use per order)

- Inventory mode

- 2D inspection for electronic components and assembled circuit boards

- Planning safely based on precise actual inventory;

- Reduction of downtime and multiple setting-ups;

- Post-order calculation of the used material immediately after completion of the process;

X-Ray inspection equipment for Lithium battery

X7800

- Detection of high-definition video: joints open, short, bubbles and other defects at a glance

- 130KV 3um closed X-ray tube with long life, maintenance free

- 1.3million high resolution digital flat panel detector

- Color image navigation

- Automatic programming detection and automatic analysis Not good or Pass

- More modular panels observation point setting

- Space bar control to adjust stage speed: Slow, Constant and Fast

- Keyboard control X, Y, Z axis motion and the inclined angle

- User can detect the samples automatically by programmed

Manual, Semi – Automatic and Fully Automatic BGA Rework Machines

ZM R5860, ZM R7850 and ZM R8650

- The industry-leading PC control system that supports software extensions,

- software installation and network monitoring

- Independent control heaters

- Adopt Panasonic automatic Vision Alignment System

- With computer operation, high accuracy K type close-loop thermocouple, and PID parameters automatic adjustment system

- Stable and Uniform Hot Air Heating System

- Adjustable Lower Heater

- Extreme Large Carbon Fiber Infrared Pre-heater

- High-Precision PID Temperature Control System

- Industrial High-Definition CCD (2 x 5.0 MP)

- Real-Time Temperature Monitoring and Over-Temperature Protection.

- Emergency Stop Function

- SMD Feeding Device Support (Optional)

- The Temperature curve can be analyzed and reported automatically, The origin can be traced if it has exceptional quality problem

- X, Y axis is equipped with micrometer fin-tuning section, adjustment precision of ±0.01mm

- Built-in three-stage smoke purification system, which can filter poisonous gas.

Automatic laser Reballing machine

ZM-ZQ1520

- Suitable for high-precision welding, accuracy ±20um, product minimum clearance 100um;

- The range of solder balls can be selected in a wide range, Diameter 0.2 mm – 0.76 mm.

- One-Click frame selection, flexible selection of target area of reballing.

- The heating and droplet dropping process is short and can be completed within 0.2s;

- The solder ball is melted in the tip, without splashing; no need for flux, no pollution, to ensure the life of electronic devices;

- The diameter of the minimum solder ball is 0.25mm, which is in line with the trend of integration and precision development;

- The welding of different solder joints can be completed by selecting the size of the solder ball;

- The welding quality is stable and the yield is high;

- With CCD positioning system, it is suitable for high-volume production of assembly lines.